Purpose of Constant Acceleration Test

The Constant Acceleration test, also known as the centrifuge test, is used to determine the effects of constant acceleration on microelectronic devices specifically for uncovered structural and mechanical weaknesses in the semiconductor package that are not necessarily detectable by other mechanical stress tests, such as the mechanical shock test and vibration test.

The Constant Acceleration test is a simulation of the operations used by military and space applications, such as a missile lunch. It will ensure that the devices under testing can structurally withstand the high-stress environments and the function of the device is not degraded after exposure to those forces.

Constant Acceleration can be used to determine the mechanical limits of the various package internal metallization or lead systems, die or substrate attachment, and other elements of the microelectronic device. It may also be utilized to validate the strengths in any of the package’s structural elements.

By establishing proper stress levels for devices that require high reliability, Constant Acceleration is generally used as an in-line 100 percent screening test. Thus, the test will help to detect and eliminate devices with lower than nominal mechanical strengths in any of the structural elements.

Constant Acceleration Test Methods

The Constant Acceleration test is applicable to both die and substrate adhesion and is defined in Method 2001 of MIL-STD-883 and Method 2006 of MIL-STD-750. According to the applicable test method, the device shall be mounted with or without the fixture on an apparatus and centrifuged in the required directions. The centrifuge force shall then apply to the devices and pull against the attached devices.

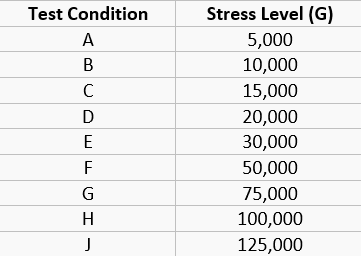

Table 1 shows the various test conditions for the Constant Acceleration test as defined by MIL-STD-883 Method 2001 and MIL-STD-750 Method 2006.

Table 1. Test Conditions:

Devices which have an inner seal —– Condition D (MIL-STD-883)

Package cavity perimeter ≥ 2 inch —– Condition D (MIL-STD-883)

Package mass ≥ 5 gram —– Condition D (MIL-STD-883)

Devices with power ratings ≥ 10watts —– Condition B (MIL-STD-750)

Hybrid packages —– Condition (A, B or C)

The Procedure of the Constant Acceleration test

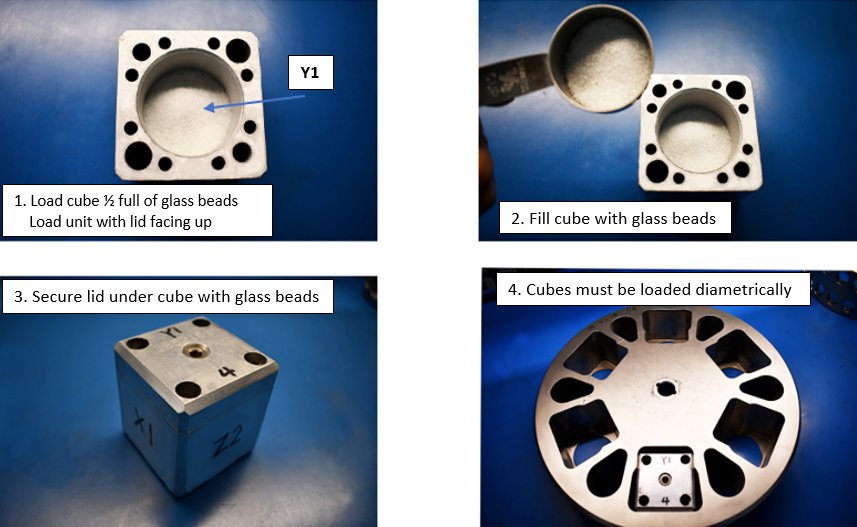

This test shall be performed on an apparatus capable of applying the specified acceleration for the required time, or by normal mountings with secured leads or cables of the devices. Unless otherwise specified, test condition E for method 2001and test condition D for method 2006, shall then be applied to the device for a 1-minute minimum in each of the required directions X1, X2, Y1, Y2, Z1, and Z2 (See Figure 1). For devices with the internal elements mounted with the major seating plan perpendicular to the Y axis, the Y1 orientation shall be defined as that one in which the element tends to be removed from its mount. (See Figure 1).

The following is a basic procedure for loading devices in the Y1 orientation:

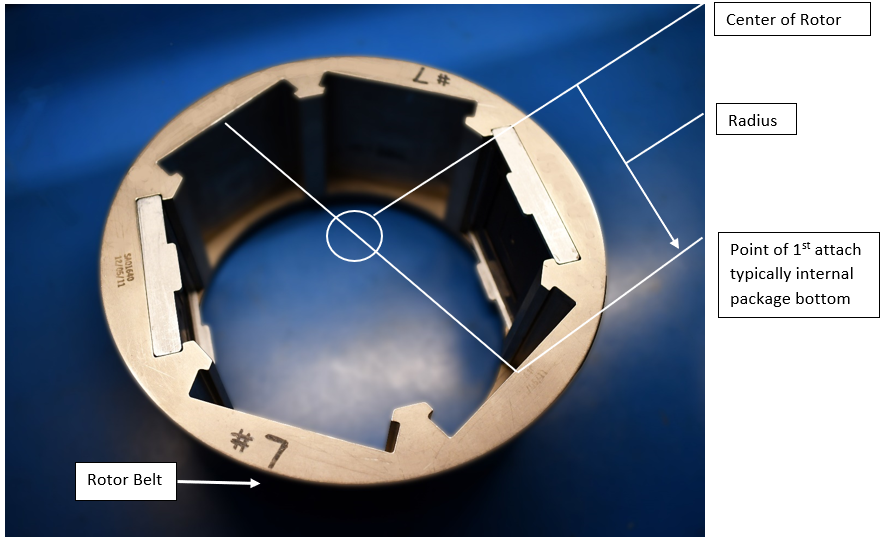

· Spin radius (R) calculation: The spin radius (R) is from the center of the bowl rotor to the 1st point of the element attachment

· Stress Level (G): The Stress Level (G) are absolute minimum with no lower tolerances

· Load the parts to the rotor: The packages shall be loaded into the rotor (with or without the fixtures) by the lid or top facing towards the outside of the centrifuge so that the centrifugal force will pull the die and bonds away from their attachment points, Y1 axis. Devices must always be evenly distributed in the rotor for proper balance. (See Figure 2)

For devices that need multiple axes tested Golden Altos uses a cube fixture. The cube can be rotated to stress the device in any direction required. (See Figure 1)

The Necessity and Impact of Constant Acceleration

Constant Acceleration is a necessary test for Military and Space level applications. Based on the specified requirements as outlined in the applicable military standard, this is one of the screening requirements which provides assurance that the tested device will be compliant with the required application. It is critical for devices that will be used in any military or aerospace application to be screened for any potential defects to ensure only the devices with the highest reliability will be used.

Potential defects identified by Constant Acceleration screening:

· Die attach or wire bond delamination

· Package or die cracking

· Structural deformation

· Sealing leakage

· Electronic circuit short or open

· PIND test failure

Constant Acceleration test with Golden Altos

Constant Acceleration is performed on devices that will potentially see the same g-force stress during the devices’ expected operating life. This mechanical testing is best done in a controlled laboratory environment. Golden Altos is listed on the DLA manufacturer list for lab suitability with extensive experience in MIL-STD-883 and MIL-STD-750 constant acceleration tests. With over 35 years of experience, Golden Altos has in-depth knowledge of Commercial, Military, and Aerospace Hi-Rel products. If you require Constant Acceleration testing for your products, reach out to Golden Altos to develop a test plan to support your needs.